Six Sigma DMADV approach- When and where it is used?

Six Sigma follows 2 improvement processes, DMAIC and DMADV. Six Sigma DMADV approach is used while developing a new process and DMAIC is used while improving the existing process. Both the methodologies are in the end focused on satisfying the customer needs.

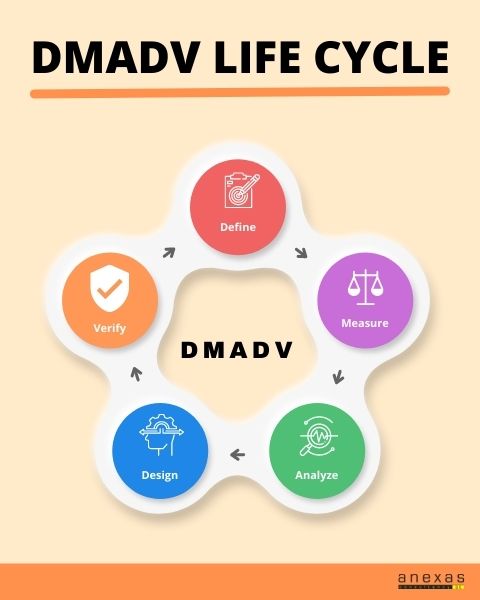

DMADV handles 5 major phases in the creation process. In this blog, you will learn more about DMADV and when the Six Sigma DMADV approach is used?

What is DMADV?

DMADV is a framework tool that primarily focuses on new processes. During the development of the process, DMADV analyses each part of the process and identifies the areas that can be improved to deliver the effective outcome

DMADV is especially useful while implementing new initiatives or strategies. Since, DMADV analyses each stage of development, it can detect the error in the early stage and can save up the cost involved in the product or service development stages.

Fundamentals of DMADV

In recent days, many companies run their project using the Six Sigma methodologies. Six Sigma DMADV approach is used to improve the process by measuring the number of errors and eliminating them. This in turn leads to lower cost of production, retaining customers and efficient use of resources.

- Define – Defining the problem to be addressed

- Measure – Measuring the key function of the process

- Analyse – Analysing to find out the best process

- Design – Designing the selected process for both high and low level

- Verify – Monitoring the process.

DMADV methodologies

As stated above, Six Sigma has 2 major methodologies, DMADV and DMAIC. DMADV is used to either redesign a problematic process or to design a new process. This methodology makes sure that each step is designed with the proper framework so that problems can be prevented from occurring.

- Define – The objectives of the project are first studied to define the problem to be addressed. It also creates a standard protocol to review the process and to keep track of work.

- Measure – Measure the key function of the process that is important to maintain the quality. You will also need to reassess the risk and check the production capability and process capability to have an effective start.

- Analyse – Develop the designs by combining all types of framework or conceptual design to find out the best process that can be implemented in the process to reduce the cycle time of the project.

- Design – The best option is selected from the previous stage. The process is then further designed in both low and high levels to add the details and required modifications.

- Verify – The customized process is then verified by the team to check if it is acceptable by the clients. The process are then cross checked to find if it fulfills the objectives of the project.

When is Six Sigma DMADV approach used

- DMAIC methodology is used to improve the existing business process

- DMADV methodology is implemented while designing a new product

- It is applied for a continuous improvement of the process

- To measure the needs of customer and increase the customer satisfaction

- To design the objectives of the project

- To produce the right product at the very first time

- To minimise the error and reduce the cycle time of the project

- It is used to assess the risk during the production and prevents from occurring

- It reduces variation to perceive the Critical to Quality (CTQ) by the customers.

Conclusion

DMADV methodology is implemented while designing a new product. This tool develops the first time right product by designing a robust plan and improving the process from the initial stage. Hence, DMADV is a better methodology to implement in the business process to deliver the best outcome when you do anything for the first time.

Click here to know more about Lean Six Sigma.

FAQs

What is DMADV used for?

DMDAV is one of the major six sigma methodologies used in various industries. It is used when designing a new process or a product. The main focus of the DMADV tool is to satisfy the customer’s needs.

What is a DMADV project?

DMADV project is a development of a new business process by following all the steps of DMADV methodology. The 5 phases of DMADV are Define, Measure, Analyse, Design and Verify

What is the difference between DMADV and DMAIC?

The most common difference between DMAIC and DMADV is, DMAIC methodology is used in existing processes whereas DMADV methodology is used while creating a new process.

What is DMADV in quality management?

Six Sigma DMADV methodology is used for quality improvement of the business process. It also verifies if the designed process fulfills the objectives of the project and the customer requirement.

What is the application of DMAIC?

DMAIC methodology is applied for the continuous improvement of the existing operations or management processes with the support of the management. It uses both the statistical and descriptive test to improve the process.

What is the application of DMADV?

DMADV is applied in the case of redesigning the process. It creates a number of processes, which is later analysed to find the best solution and alternative choices to run a process.

What is the DMAIC process and how does it differ from Six Sigma?

Six Sigma consists of 2 main methodologies, DMAIC and DMADV methodologies. It is a part of the six sigma methodologies that is implemented to improve the quality of the existing process.