Lean Six Sigma in Software Engineering

Lean Six Sigma in Software Engineering

Lean Six Sigma is a collaboration of lean production and six sigma methodologies. It is a widely used tool across companies to improve the process in the business. It eliminates the waste processes and the errors to reduce variation. Lean Six Sigma also provides a framework for the new processes.

Lean Six Sigma in software engineering provides solutions to increase the production and quality of the process. Application of Lean Six Sigma tools in the software methodologies gives a massive improvement in their business output. In this article, we will study the applications of Lean and Six Sigma in software engineering.

History of Lean Six Sigma

Six Sigma was developed by Motorola to compete with Kaizen which developed Lean manufacturing. Initially, each methodology was applied separately in industries for detecting tools and improving the quality and efficiency of the process. After years, the Toyota production system developed Lean as a single process in the 1950s.

Lean Six Sigma improves the quality of the process by identifying defects or errors and eliminating it. Six Sigma and Total quality management (TQM) maintain the standard quality of the process. Both these methods are similar but have one difference, and that is their way of approaching and focusing on the problem. Lean eliminates the error and focuses on a holistic approach whereas Six Sigma focuses on the problem individually. Hence, Lean Six Sigma tools and techniques are more popular in software development.

What is software engineering?

As the name states, it is a branch of engineering that deals with the development of software products. It examines the needs of the customer and accordingly software developers design, build and analyze the end product to test if it satisfies the customer’s requirement. It is an application of engineering techniques in software development.

Lean Six Sigma rules in software engineering provide a structured framework for continuous improvement and waste reduction. By applying Six Sigma principles, such as DMAIC (Define, Measure, Analyze, Improve, Control), software engineering teams can identify bottlenecks, streamline processes, and optimize resource utilization. The Lean approach complements this by eliminating non-value-added activities, reducing cycle times, and improving overall efficiency. For example, in software testing, Lean Six Sigma can help identify the root causes of defects, improve test coverage, and enhance the effectiveness of defect management processes. In quality assurance, Lean Six Sigma principles enable the identification and elimination of waste in documentation, review processes, and quality checks. Through the integration of Lean Six Sigma in software engineering, organizations can achieve higher levels of quality, productivity, and customer satisfaction.

The combination of PSP (Personal Software Process) and Six Sigma in software engineering creates a formidable approach for achieving excellence. PSP empowers individual developers to improve their personal productivity, estimate effort accurately, and track defects meticulously. It instills discipline and efficiency in their work, leading to high-quality code and reduced errors. When integrated with Six Sigma, a data-driven approach to process improvement, organizations can analyze and optimize software development processes at a broader level.

Introduction to software

Software is a set of programs that contains a set of instructions to develop a product or an application. Any software that we use has much more than what we can see. Constructing software is not as easy as it seems. It delivers the computing potential to many hardware across networks and delivers the function effectively. IT also transforms the information to design or build models that can serve the crowd.

Types of software engineering

- Game designer

- Software Integration engineer

- Front End Engineer

- Back End Engineer

- Full Stack engineer

- 3D Graphics developer

- Data Scientist

- CRM project manager

- DevOps Engineer

- Security Engineer

Characteristics of Lean Six Sigma

| Characteristics | Description |

| Statistically driven quality improvement | Six Sigma tools are more statistical and data driven. They improve the quality of the business process. |

| Methodology | Application of DMAIC and DMADV methodologies to improve the existing and new process respectively. |

| Objective approach | Lean Six Sigma emphasizes on the objectives of the sigma project |

| Customer Satisfaction | Lean Six Sigma tools focus on reducing variation to increase customer satisfaction. |

| Quality control | Lean Six Sigma collaborates with different departments and increases the overall quality management. |

Lean Six Sigma Methodologies

The major commonly used methodologies in six sigma are DMAIC and DMADV methodologies. Each methodologies analyze five sections of a process. Both the methodologies are used for software testing and quality assurance.

The integration of Six Sigma in software project management brings a powerful framework for driving efficiency and quality throughout the project lifecycle. By leveraging the principles of Six Sigma, project managers can meticulously define project requirements, measure critical metrics, analyze processes, and identify areas for improvement.

DMAIC

DMAIC methodology is used to improve the quality of the existing process in the company

Define – Define the problem and goals of the project.

Measure – Measure the details in every aspect of the business process.

Analyze – Examine the data and detect the root causes of the error.

Improve – Improve the quality of the process.

Control – Control the process and ensure that the improvement in the process is maintained.

DMADV

DMADV is used to create a new process and setting the standard and procedures for the process

Define – Define the goals of the project.

Measure – Measure the key function of the process.

Analyze – Analyze the various processes and select the best one.

Design – Design the process.

Verify – Verify the process by testing them and detecting the possible risks.

DMAIC In Software Engineering

DMAIC is an effective tool used to improve the existing process. It consists of tools such as control charts, scatterplot, 5 whys, regression analysis, pareto charts, and many problem solving tools. These are called 7 – M tools. It does not directly contribute to the development of the software, but improves the process involved in it. Value stream mapping helps in designing the process from first to last. It improves the existing process by reducing the cost involved in it and decreases the variation and cycle times.

DMAIC can be applied to software development as any other process. The improvement opportunities in the software company are converted into improvement projects and trained Green Belts and Black Belts are assigned to them. Goals of the project are defined and the problem statement that has to be addressed is identified to improve the process. Similarly, each aspect of the process is analysed to study the factors that might cause defects in the process.

Six Sigma methodologies ensure that the quality of the process is maintained from the initial step. It conducts tests like unit tests and integration tests before implementing the process. Six Sigma sets up toll gates in each project phase to monitor and review the performance. Tollgate improves the success rate of a project. CTQ analysis finds the requirements and ensures the focus on the deliverables. Lean and Six Sigma in software engineering is advantageous in plenty of ways compared to other tools and techniques.

DMADV in software engineering

DMADV is also similar to DMAIC. DMADV is applied while creating a new process whereas DMAIC is used to improve existing processes. DMADV is a statistically driven quality tool. It creates solutions for customers to address problems related to cycle time, access and frequencies transaction, and many more.

DMADV captures the voice of customers (VOC) using tools like QFD (Quality function deployment) to design the technical requirements. It defines the roles of the project. It measures the customer-related metrics and accordingly adjusts their goals to increase productivity and accept the change. It also helps in the integration of the different solutions to streamline the process and provide a single solution. DMADV methodology aligns the goals of the project and verifies if the process is followed according to the set norms. Lean Six Sigma in software engineering has positively impacted the IT industry.

Introduction to Agile

Agile is a method of dealing with a process i.e. to create and to respond to change. In other words, agile is meant for adaptiveness and an effective response to a change. Agile Software development is more than a framework like Feature Driven development. The frequently used agile project methodology is scrum. It is used to improve the software development of the product. It provides solutions to workforce planning, for example: ‘how to work together in a team and carry forward the activity’. It follows the practices such as pair programming, test driven development, strategic planning, sprints and stand ups.

Agile methodology emphasizes project management whereas Lean Six Sigma improves the quality of the process. On collaborating both the methodologies we can focus on continuous improvement of the process along with the management support and performance speed. Lean Six Sigma methodology, DMAIC and DMADV integrating with agile has plenty of benefits. DMADV studies customer requirements and their performance expectations. Accordingly they are prioritized and tested to verify the process to see if it has achieved its set goals.

Lean Six Sigma in Agile and Software Development

Every software development model expects the process to be right. Integrating Lean Six Sigma with agile models tries to deliver efficient work outputs. Lean Six Sigma checks if the process is followed and is cost efficient. Software companies develop a customised agile software, scrum. This aligns the management and supports them to deliver the process, while Lean production deals with the conflicts, project planning and process improvement.

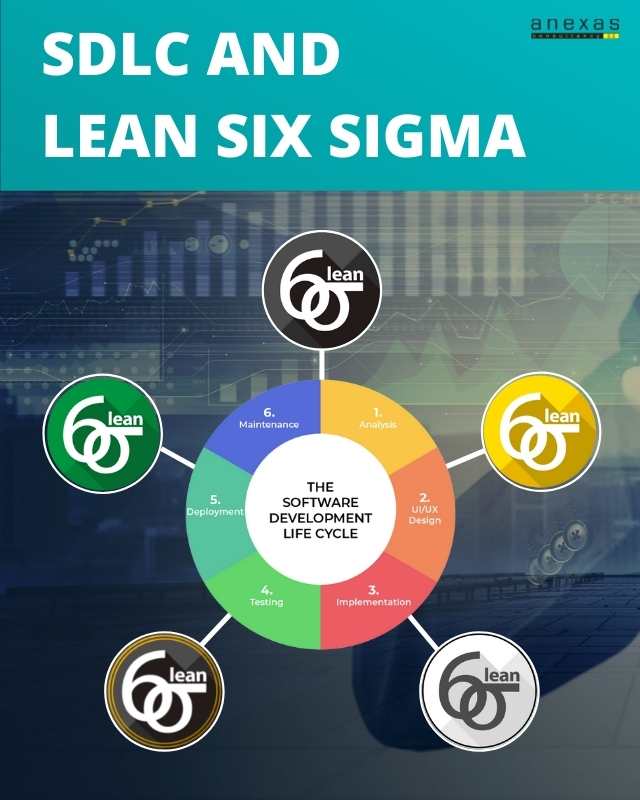

SDLC

SDLC stands for Software Development Life Cycle. It is a systematic process of building software with quality and rightful process, SDLC consists of seven phases explaining how to build, implement and maintain the software. Each phase has its roles and responsibilities. Deliverables of the prior phase are fed to the next phase for the continuous process.

Lean Six Sigma Tools in SDLC

SDLC has different models like waterfall model, agile model, spiral model, incremental model and many more. These are implemented to design the complete process in the development of new processes. Integrating Lean Six Sigma toll in SDLC lifts the process by analyzing each stage of designing. This small effort can bring the best outcomes. It advances each process and improves the quality and the project cycle time. It finds the root cause of the critical or frequently occurring problems and provides a solution as well, contributing to software testing and quality assurance.

Some of the commonly used Lean Six Sigma tools in SDLC are

- Value stream mapping

- Kano

- Kanban

- Roadmaps

- Regression analysis

- ANOVA

- Control charts

SDLC with Lean Six Sigma

| S.No | Parameters | SDLC with Lean Six Sigma | SDLC without Lean Six Sigma |

| 1 | Quality Improvement | ✔ | ✘ |

| 2 | Toll Gates for review | ✔ | ✔ |

| 3 | Design Review | ✔ | ✔ |

| 4 | Code Review | ✔ | ✔ |

| 5 | System Testing | ✔ | ✔ |

| 6 | Integration Testing | ✔ | ✔ |

| 7 | Process Mapping | ✔ | ✘ |

| 8 | Quality Function Deployment | ✔ | ✘ |

| 9 | Hypothesis Test | ✔ | ✘ |

This data-driven approach enables proactive risk management, efficient resource allocation, and effective quality control. By applying Six Sigma methodologies, project managers can streamline workflows, reduce defects, and optimize resource utilization, and ensure that software projects are delivered on time, within budget, and with superior quality. With Six Sigma in software project management, organizations can maximise project success, enhance customer satisfaction, and gain a competitive edge in the dynamic software development landscape. PSP and Six Sigma in software engineering can be implemented together for improved processes.

10 Concepts under Lean Six Sigma

- Kaizen

This has become an integral part of Lean Six Sigma strategy and is followed in every company to work together to get continuous improvement of the process.

- 7 Wastes

The most commonly produced 7 wastes in IT processes are-

- Inventory

- Overproduction

- Defects

- Over processing

- Waiting

- Transport

- Motion

- Mistake Proofing

Also known as Poka-Yoke is used to identify the defects or human errors and prevent them from occurring.

- Value stream Mapping

It is a method of analyzing the existing flow plan and checking if any change is to be done in future process flow.

- Line Balancing

It is a concept to ensure continuous flow of work through the steps and eliminate bottlenecks.

- Productive Maintenance

A physical management strategy to maintain the manufacturing of the machineries by reducing the cost of rebuilding.

- 5S System

5 major steps in the standardizing process namely sort, set in order, shine, standardize and sustain.

- Cost Reduction

Reducing the cost by decreasing the variation in process.

- Defect reduction

Lean Six Sigma emphasizes on detecting the error or defect and reduces it by preventing it from occurring.

- Quality improvement

It reduces the variations and improves the quality of the process and increases customer satisfaction.

Click here to register for the upcoming Lean Six Sigma Yellow Belt session.

Case study

To compete in today’s world, businesses require a structured approach, disciplined thinking, and the engagement of everyone in the organization . The software industry is no exception. In recent years, software has become an increasingly important component in consumer products and capital goods industries. More and more products contain multiple software components (embedded systems), and depend on it for many of their functions.

The service industry has also not remained untouched with software playing an important role in many service industries such as telecoms, banking and insurance. As a result, the criticality of software quality cannot be ignored. Poor software quality results in delayed, failed, abandoned or rejected software projects. Even those software projects already implemented may need expensive on-going maintenance and corrective releases or service packs for assuring good software quality.

The software should be easy to use and properly structured that would make it easy to maintain. However, with today’s market competition and the need for rapid delivery, software quality is often sacrificed, thus leading to failure of the software projects. Also, the use of traditional methodology such as waterfall plays a major role in reduced software test coverage, and as a consequence poor software quality. Moreover, people jump to solutions without fully understanding the problem or finding the root cause of poor quality.

Six sigma can be best described as a business process improvement approach that seeks to find and eliminate causes of defects and errors, reduce cycle times and cost of operations, improve productivity, better meet customer expectations, and achieve higher asset utilization and returns on investment in manufacturing and service processes. The objective of six sigma is to increase the profit margin, improve financial condition by minimizing the defects rate of product. It increases the customer satisfaction, retention and produces the best class product from the best process performance. It is based on a simple problem solving methodology – DMAIC, which stands for Define, Measure, Analyze, Improve, and Control.

Conclusion

Software engineering is the development of an application or a program to serve the customer. It is quite a tedious process, because even if one activity is messed up, the whole process will come to a halt. Lean Six Sigma is a key tool that can analyze each step involved in the development; be it any model, the tools enable them to continue the process without any defect or error. If these are taken care of in the early stage of development, it can reduce the cost of re-development and can save time.

FAQs

What is Six Sigma?

Six sigma is a tool used in many companies and organizations. It improves the quality of the process. The 2 major methodologies are DMAIC and DMADV. It decreases the variation and increases the customer satisfaction.

Do you offer Lean Six Sigma training and certification?

Yes, Anexas Europe offers Lean Six Sigma training and certification at the best price.

What is a Master Black Belt?

Master Black belt is the top level certification exam in Lean Six Sigma. They are responsible for teaching methodologies to black, yellow and green belt candidates. They are also eligible to lead and direct projects.

What is a Black Belt?

Lean Six Sigma black belt is the second highest level of Six Sigma certification. It gives you a complete understanding of the concepts and methodologies such as DMAIC and DMADV and also helps you identify the wasteful process.

What is the difference between Lean and Six Sigma?

Both the techniques are used in the improvement of the business process. Six Sigma focuses on the quality of the process and lean focuses on speed of the process by eliminating the defects and errors.

Does Lean Six Sigma benefit a software engineer?

Yes, it will definitely benefit a software engineer. In recent days, most of the corporate companies deliver their projects using Lean Six Sigma methodologies. Acquiring this certification can increase your career opportunities.

Is Six Sigma good for software engineering?

Lean Six Sigma methodologies help in the development of an application or a product by streamlining the processes involved. The tools are also used to improve the quality of the process and reduce the cost.