In this article, you will be introduced to the concept of Lean and 8 wastes in the process, different methods to identify the 8 wastes in the process, and how to eliminate 8 wastes of lean, simplify, combine, automate, and parallel processing of activities. For any business, whether its output is a Product or Service, waste is an inherent part of the process, and understanding Lean Six Sigma will help you in process improvement to achieve organizational goals.

Let us discuss the nature of waste:

- By the term “waste”, we do not mean the waste comes as a by-product of the process

- We define waste as anything in the process which doesn’t add value to the product, or the customer is not willing to pay for it.

- Waste is found in management systems, communications, human resources, finance, operations, projects, and procedures.

- Everywhere you should develop an eye for any waste present in the process.

- You should be trained to look for 8 wastes in your process.

What are 8 wastes in Lean Six Sigma?

We define 8 wastes in Lean Six Sigma as the activities that are adding no value to the product or service or in other words for which the customer is not willing to pay. We often use an acronym for the 8 wastes of lean manufacturing which is DOWNTIME, It stands for Defects, Overproduction, Waiting, Not utilizing talent, Transportation, Inventory excess, Motion waste, and Excess processing.

We will discuss these 8 wastes in detail in the next sections

8 types of waste in Lean Six Sigma

Defect (Scrap/Rework/Errors):

The first waste is defects or correction. It is the most obvious waste, if the process is not done right the first time then the waste is created like scrap, rework, repair, etc. which requires extra processing. How does this affect the process?

- It reduces the capacity per minute in all areas of the enterprise including operations, maintenance, engineering, management, administration support functions, etc

- There are no exceptions. For example, the defect could be incorrect vendor information, a wrong record of the document, dialling the wrong number in a phone call, etc.

Overproduction:

The other type of waste is overproduction. Producing more than what is required, producing more than the demand from the customer, and producing faster than needed to meet the customer demand is overproduction. A few more examples are:

- Material or product is overproduced to cover problems such as equipment efficiencies, process coordination, and fear of future material or part shortages.

- World-class practices mean producing what is needed when it is needed and in the amount that is needed so you should produce just in time the quantity which is needed by the customer.

Waiting:

Waiting to use a tool, equipment, machine, or another process to finish waiting on the paperwork instructions, schedule information, etc. Waiting for a decision, waiting for parts, help, tools, equipment repairs, or waiting for a meeting to start, comes under this waste. These often result in:

- Unbalanced cycle times, meaning in a continuous flow if different process steps are taking different times, then it would result in waste. Because if the times are different, one of the processes would finish the work fast and the next process must wait if the previous step is slow.

- So, we need to balance the line. All the steps should be taken at almost the same time. Otherwise, it would result in waiting for approvals, waiting for cost estimation before completing the design review process or waiting for inputs etc.

Intellect (Not utilizing talent):

Waste of intellect is related to the utilization of skills and knowledge of employees. For example, hiring a PhD graduate and assigning a data entry job. Not involving the person doing the job, for the real expert they are in, is missing improvement results. A few examples of a waste of the human mind:

- Not listening and acting on ideas for the elimination of waste.

- Not listening to suggestions.

- Not being able to make decisions about correcting or improving the process.

- Not providing training, not putting into practice what we have learned, not providing people with the knowledge required to do the work.

Transportation:

The movement and transportation of materials and products other than necessary as part of the value-adding processes wastes. Moving a product from one place to another does not add a customer’s desired characteristic which the customer perceives as a value, moving stock or materials from operation cooperation is a waste. A few more 8 wastes examples are:

- Repetitive movement of products or materials, and back treatment, are all examples of waste.

- Some other examples could be excessive movements of documents and movement of people. In-person meetings involving travels, when you can perform video meetings.

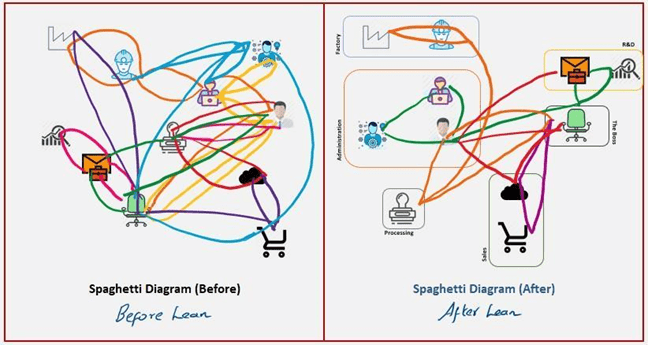

- One of the ways to identify the waste of movement or transportation is by making a spaghetti diagram.

Inventory:

Inventory causes waste of space, transportation, processing materials, etc. It is expensive to store, transport, count, or audit. If you have too much inventory that is not required for processing, it is often used as insurance against shortages, it causes problems because it makes unnecessary storage. A few more examples are:

- Holding, taking more than needed, and not returning material tools or parts or supply cabinets after using.

- Waiting until sufficient work volume accumulates to begin working (that is batch processing), instead of following the continuous flow ordering (additional parts as a buffer or insurance against the shortages).

Motion/ Movement:

Movement waste is generally within the facility and within the office premises (transportation waste refers to transportation across long distances). For example, Waiting for a face-to-face meeting schedule when an email or telephone call could be sufficient. A few more examples are:

- If the workplace is poorly arranged and too many steps must be taken between the processes, accounting has to locate several files in databases to prepare a customer invoice.

- People don’t check if anyone needs anything before leaving the work area to go to the shop floor or supply room.

- Wrong tools and equipment brought out to work areas having to go back again and again for getting the right tool.

- Motion also refers to bending, reaching, squatting, walking, twisting etc. Sometimes also called “ergonomics”.

Over-processing(Excess processing):

Overprocessing refers to the unneeded steps in the process. Some of the examples in your area could be extra or unnecessary instructions, overwritten emails, record memos or reports. Filling out additional paperwork that does not improve a service or the timely delivery of completion. A few more examples are:

- Extra steps in the process of servicing equipment.

- Creating a process to correct mistakes, when mistakes could be eliminated or corrected in the process.

- Doing more than it is required to produce a quality product.

How to reduce waste in lean Six Sigma?

Lean Six Sigma waste elimination can be achieved by various techniques that are mentioned in the Lean Six Sigma course. These techniques are very useful to identify and act on the 8 types of waste in Lean Six Sigma present in the process. The techniques are mentioned below:

Spaghetti technique:

The spaghetti technique helps in reducing the unnecessary waste of motion. Here in this tool we draw a spaghetti diagram for the movements involved in the shop floor or the workplace and try to reduce the unnecessary motion present in the process.

VSM:

Another tool to use for the elimination of waste is value stream mapping. It is a process map that helps in identifying unnecessary steps and waste present in the process. It also indicates the opportunity for improvement in the process.

8 wastes of lean timwood highlight the eight core wastes hindering operational efficiency: Transport, Inventory, Motion, Waiting, Overproduction, Over-processing, Defects, and Skills. Addressing these allows businesses to streamline processes and amplify productivity.

Read the blog value stream map for more information.

ESCAP analysis:

We can also use the ESCAP technique. ESCAP stands for; eliminate, simplify, combine, automate, and parallel processing of process steps. These are the techniques we can use for the elimination of waste in a process

Watch a video on ESCAP technique for more information.

- Eliminate– In Eliminate, we try to eliminate any unnecessary non-value-adding process steps and make the process as simple as possible. There is a hidden factory present in any process which involves lots of waste.

- Simplify: In Simplify, we try to reduce the number of steps or the complexity of a process where our goal is to make the process more ergonomic and with lesser complexity.

- Combine: In Combine, we try to combine two or more process steps and make one process step which can add the same value to the product or service involving lesser steps and lesser waste.

- Automation: Automation is a need of modern technology which generally can be seen in any manufacturing process with emerging technologies. It talks about human-machine intervention which can reduce waste drastically. Human-machine involvement in building automation in a process is called “Jidoka” in Japanese

- Parallel activity: Doing two or more processes in parallel can greatly save the time of processing and that’s why we try to find the scope of parallel processing of 2 activities while assessing any process for waste elimination.

- 5S workplace management methodology: 5S is a workplace management methodology which can be implemented at any place where a process is taking place. The 5S involves Sorting, Setting in order, Sweeping, Standardization, and Sustaining.

Read Workplace Management 5S blog for more information

OEE (overall equipment effectiveness):

OEE is calculated for a machine/ equipment by multiplying Availability, Performance and Quality. These 3 terms are indicators of different parameters which are important in terms of waste in the process

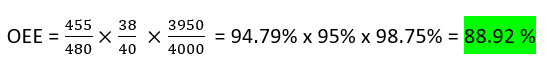

- OEE = Availability x Performance x Quality

- Where, Availability = total time available for processing / Total Shift time (excluding planned stops e.g., lunch breaks, tea breaks, planned maintenance)

- Performance = Expected Cycle time (theoretical) / Actual Cycle time (Practical)

- Quality = Total Good pieces manufactured / Total no. of pieces processed.

- For example, in a manufacturing facility shift time was 8 hours and planned shutdowns are 30-minute lunch breaks and two 10 minutes tea breaks. Total production loss due to breakdown was 25 minutes. The cycle time for manufacturing one piece was 40 seconds and the expected cycle time was 38 seconds at the end of the shift, a total of 4000 pc. manufactured out of which 3950 pieces were found OK.

To calculate OEE following steps are required

Total time for processing = Total shift time – production losses = 480-25 = 455Min

Total Shift time (excluding planned stops) = 8 Hrs x 60 min/Hr = 480 minutes

Expected Cycle time (theoretical) = 38sec

Actual Cycle time (Practical) = 40 sec

Total Good pieces manufactured = 3950 Nos.

Total no. of pieces processed = 4000 Nos.

OEE = Availability x Performance x Quality

Example Exercise1: What does the abbreviation ESCAP mean?

- eliminate, simplify, combine, automate, and parallel

- eliminate, specify, combine, automate, and plan

- eliminate, simplify, cluster, automate, and parallel

- eliminate, simplify, combine, align, and plan

Answer: Option 1 is correct. The ESCAP technique – full form is to eliminate, simplify, combine, automate, and parallel processing of process steps these are the techniques we can use for elimination of waste in a process.

Example Exercise2: The importance of Identifying and reducing wastes in a process is to

- Improve efficiency.

- Reduce unwanted steps.

- Reduce non-value adding activities.

- All the Above.

Answer: 4) is the correct option. Waste reduction helps in Improving efficiency, reducing unwanted steps, and reducing non-value-adding activities.

Example Exercise3: When team members are sitting in a meeting room waiting for another meeting to finish before they can start their meeting, this is an example of which type of waste?

- Waste of inventory.

- Waste of motion

- Waste of waiting.

- Waste of Intelligence

- Waste of overprocessing

Answer: Option 3) is correct. “Waste of waiting” is defined as the amount of time waiting for one process to complete so that we can start another process step, then it is called a waste of waiting.

Conclusion

Every process has some wastes, and it is defined as any activity which is not required by customers or not paid by the customers for. These are called 8 wastes in the Lean process. These non-value-adding activities need to be removed by various methods and techniques. The aim is to eliminate, simplify, combine, automate, parallel, process these wastes. We can also measure the wastes and calculate overall equipment effectiveness since waste in a process is directly related to the process efficiency, which is the objective of lean and six sigma.

Also read: Lean Six Sigma: Value Stream Mapping