Table of Contents

Share This Article

Poka Yoke: Streamlining Processes for Lean Six Sigma Success

- 27916 views

Let us talk about Poka Yoke, a tool widely used in Lean and also now integrated into Lean and Six Sigma implementations. Poka Yoke Lean tool, also known as mistake-proofing, was coined in the late 60s by Shigeo Shingo who helped design the process and worked as a quality control professional. Earlier it came out to be as Baka-Yoke, which means idiot in Japanese, and later for an inadvertent mistake was termed Poka-Yoke. Sometimes also referred to as idiot-proofing to indicate that a system should be designed such that even fools should not be able to commit a mistake, this topic is easy to understand but requires some guidance.

What is mistake proofing in Lean Six Sigma? Poka-yoke Six Sigma is simply a tool that helps you fix as well as prevent inadvertent errors caused by humans such as processing wrong material or workpiece, not following standard practices or procedures or not maintaining equipment. One of the notable poka yoke examples is the design of car keys that can only be inserted into the ignition in one correct orientation, preventing the user from making a mistake. In the world of quality management, various poka yoke types are employed to prevent errors and enhance productivity across different industries. his is one of the most important topics in the Lean Six Sigma Black Belt and needs to be given attention in order to understand it correctly. Mistake proofing or Poka Yoke is a key principle in Six Sigma, ensures error prevention and in this article we will understand mistake proofing examples showcasing its effectiveness.

Poka-Yoke- How to solve & tips

There are a total of 12 tips to complete Poka Yoke Lean tool correctly. These tips are carefully designed by our industry experts for implementing mistake proofing in Lean Six Sigma and they are as follows –

- Source of errors could be from equipment and material likely by improper setup, adjustment error, excessive wear, poor maintenance, and overburden and also uneven production could be followed by missing, wrong or defective parts.

- Poka-yoke helps avoid even a simple error in your own workplace. It shows more miraculous results when clubbed with ‘2 second lean’. The idea undertaken is to nullify the repetitive tasks which rely on error and lapses behind the wall of focus. It is one of the common branches of the tree, Zero-Defect Quality Control.

- The main aim of this technique is to reduce the risk of mistakes or errors, minimise the effort required to perform activities, and detect errors prior to them impacting people.

- Ideally, Poka-yoke can be distinguished as prevention-based or detection based.

- In the prevention type, poka-yoke does not allow or have the possibility for the occurrence of any mistake, as it does not allow the process to begin or continue if an error has occurred. Let’s say while inserting a sim-card, the cavity won’t go in unless the sim-card is placed as designed.

- Not all problems or errors can be eliminated but a warning can be provided. Here, poka-yoke allows the error to be but alerts the user to make it right. The only thing to ensure with this poka-yoke is that error is investigated and appropriate actions are taken.

- All mistake-proofing activities fall under one of these three categories: Contact method, Fixed-value method and Motion step method.

- Contact method is based on verification which detects oddity with respect to design or standard and responds back accordingly. Let’s say the orientation of a plate should match with a notch. Locator pins, switches, notches, and fixtures respective to design can help through it here.

- Fixed value method is based on verification of count, value or number of items or else number of events to be followed. Let’s say 15 balls are required to complete a packed box, the same number of shelves in the box shall be made prior, which gives a visual check confirmation.

- Motion sequence method verifies whether layered operation or sequence is followed.

Apart from the above methods, 6 principles are followed by this technique.

- Elimination (“don’t do it anymore”) is to eliminate the possibility of error by redesigning the product or process so that the task or part is no longer necessary.

- Prevention (“make sure it can never be done wrong”) is to design and engineer the product or process so that it is impossible to make a mistake at all.

- Replacement (“use something better”) is to substitute a more reliable process to improve consistency.

- Facilitation (“make tasks easier to perform”) is employing techniques and to combine steps to make work easier to perform.

- Detection (“notice what is going wrong and stop it”) is to identify an error before further processing occurs so that the user can quickly correct the problem.

- Mitigation (“don’t let the situation get too bad”) is to seek to minimise the effects of errors.

- Elimination, Prevention, Replacement and Facilitation are to avoid the occurrence of mistakes. Detection and Mitigation are to minimise the effects of mistakes once they occur.

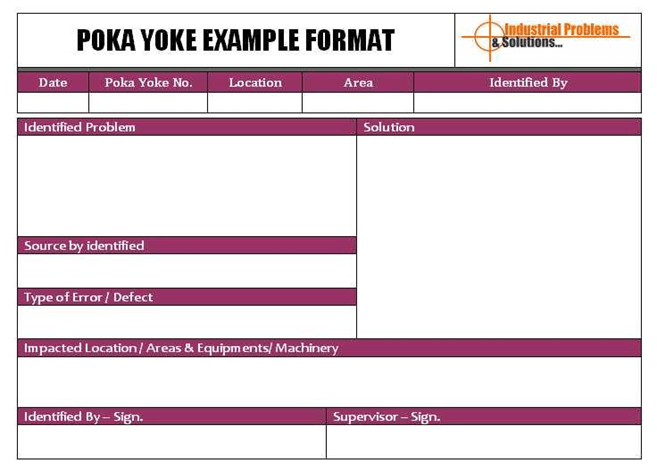

How to implement Poka-Yoke?

- Study the complete process, operation or steps involved in detail, jot down the errors from the sources.

- Use FMEA in the sector you are in to review and analyse the process in an effective manner.

- Use the charter to initiate and keep track by jotting down identified problems, their source, type and area of impact. It can be done for multiple locations, equipment and processes

- Make a matrix of Cause of defect v/s Human error, giving a score to it, one can analyze the priority and type to be implemented.

- List down the best implementable solution to each. Redesign to eliminate the chances of errors followed by detection type where prevention is not applicable.

- Implement the best method or device for each error.

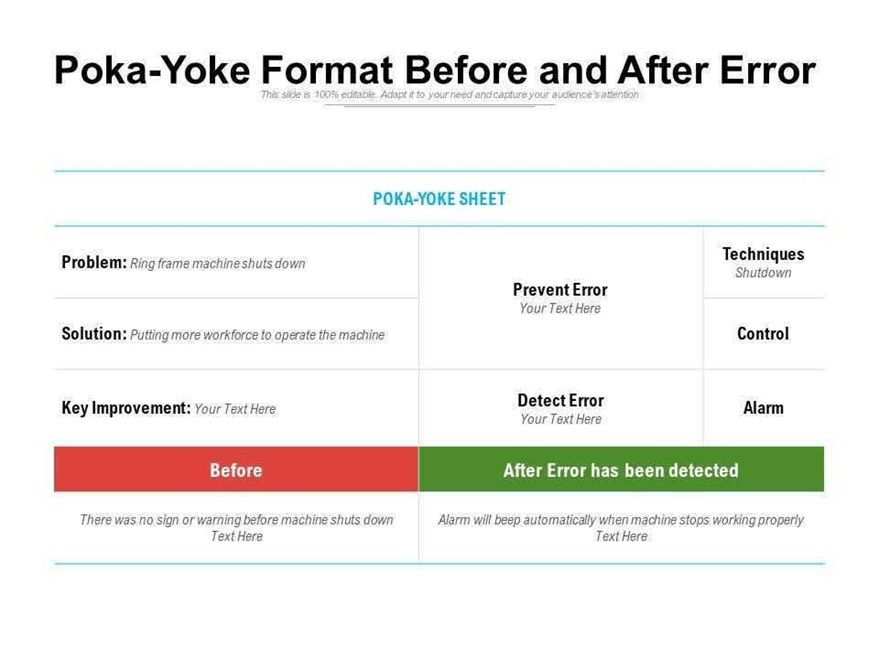

- Use before-after to document the above. A checklist can be followed to monitor the proper functioning of poka-yoke implemented at a regular duration

- Poka Yoke Six Sigma has been widely used not only in Japan but in every sector leaving a productive as well as an appreciable mark. An example of poka yoke is the use of color-coded connectors in electronic devices, ensuring that each component is connected to the correct port, reducing the risk of incorrect connections and potential damage. From physical devices like sensors and checklists to digital solutions such as automated error detection algorithms, a wide range of poka yoke types exists to eliminate mistakes and improve overall process reliability.

- Some benefits of Poka-Yoke are-

- elimination of set-up errors and improved quality

- decreased set-up times with associated reduction in production time and improved production capacity

- simplified and improved housekeeping

- Increased safety

- lower costs

- lower skill requirements

- increased production flexibility

- Improved operator attitudes.

Poka Yoke in Lean Six Sigma examples- different industries

Poka Yoke examples in manufacturing industry

By implementing poka yoke techniques, manufacturers can mitigate costly errors, enhance product quality, and boost overall efficiency. Numerous poka yoke examples can be found in the manufacturing sector, where the emphasis lies on preventing defects and ensuring smooth operations. For instance, the use of specialized jigs and fixtures that only allow parts to fit together in the correct orientation is a classic poka yoke example in manufacturing. Similarly, incorporating sensors in assembly lines to detect anomalies or deviations from standard specifications serves as another effective poka yoke in manufacturing. In the realm of lean manufacturing, where waste reduction and continuous improvement are paramount, poka yoke plays a crucial role by identifying and eliminating potential sources of errors, leading to streamlined processes and enhanced productivity.

Poka Yoke examples in the Autombile Industry

The application of poka yoke principles in the automobile industry has been instrumental in improving safety, quality, and efficiency. Various poka yoke examples can be found throughout the manufacturing and assembly processes of automobiles. For instance, the implementation of error-proofing mechanisms during the assembly of engine components ensures that parts are correctly fitted, preventing costly defects or malfunctions. Another notable example is the design of car keys with unique shapes or electronic coding that can only be inserted into the ignition in one specific way, reducing the likelihood of ignition-related errors. Additionally, modern automobile manufacturing incorporates sophisticated sensors and warning systems that detect potential faults or abnormalities in real-time, enabling timely intervention and maintenance.

Poka yoke examples in the Service industry-

By incorporating poka yoke techniques, service providers can ensure accurate and error-free delivery of services, leading to enhanced customer satisfaction and loyalty. Several poka yoke examples can be observed in various service sectors. For instance, in the hospitality industry, hotels utilize keycard systems that prevent guests from leaving their rooms without returning the keycard, reducing the risk of lost or misplaced keys. In the healthcare sector, the use of barcode scanners during medication administration helps nurses verify the correct medication and dosage, minimizing the potential for medication errors. Moreover, online booking platforms often include automated error-checking mechanisms that prompt users to correct mistakes in their personal information or travel dates, ensuring accurate bookings.

Poka Yoke examples in Offer-

In an office environment, poka yoke examples can be found in various processes and systems. For instance, standardized templates and checklists ensure consistency and accuracy in document creation and review. Email filters and rules help prevent important messages from getting buried in overflowing inboxes, ensuring timely responses. Another example is the use of color-coded filing systems that help employees quickly locate and retrieve documents, minimizing the risk of misfiling or losing important information. Additionally, automated spell-check and grammar tools in word processors serve as poka yoke measures, catching errors before documents are finalized and shared.

Poka Yoke examples in warehouse-

In the fast-paced world of warehouse operations, poka yoke principles play a vital role in optimizing efficiency and minimizing errors. One common example is the use of barcode scanners and automated inventory systems that prevent incorrect product placement or shipment by scanning and verifying product codes. Additionally, color-coded labels and signage guide warehouse personnel to the correct storage locations, reducing the risk of misplacement and facilitating easy retrieval. Furthermore, the implementation of visual indicators, such as floor markings or signs, helps maintain clear pathways for equipment and personnel, preventing accidents and optimizing workflow.

Poka Yoke examples in daily life-

Numerous poka yoke examples can be observed in our routines, enabling us to avoid errors and simplify tasks. For instance, the design of a USB connector with a specific shape that can only be inserted in one direction ensures hassle-free and correct connectivity. Similarly, the presence of warning labels and safety mechanisms on household appliances like toasters or hairdryers serves as a poka yoke measure, preventing accidental misuse and promoting user safety. In our digital interactions, auto-correct features in text messaging applications act as poka yoke by automatically correcting spelling errors, saving us from embarrassing mistakes.

Lean Six Sigma Green Belt Certification Poka-Yoke example 1

Mistake proofing in Japanese termed as

Lean Six Sigma Green Belt Certification Poka-Yoke example 2

Prevention is __

Lean Six Sigma Green Belt Certification Poka-Yoke example 3

Mitigation is __

Lean Six Sigma Green Belt Certification Poka-Yoke example 4

Detection is __

Answers for skills building exercises

Answer for the first sample exercise is : Poka Yoke, also known as mistake proofing, was coined in the late 60’s by Shigeo Shingo who helped design the process and worked as quality control professional.

Answer for the second sample exercise is : Prevention (“make sure it can never be done wrong”) is to design and engineer the product or process so that it is impossible to make a mistake at all.

Answer for the third sample exercise is : Mitigation (“don’t let the situation get too bad”) is to seek to minimise the effects of errors.

Answer for the fourth sample exercise is : Detection (“notice what is going wrong and stop it”) is to identify an error before further processing occurs so that the user can quickly correct the problem.

Also read: Lean Six Sigma Green Belt Certification Affinity Diagram