DMAIC Methodology in Lean Six Sigma

- By Amitabh Saxena

- 28916 views

Table of Contents

Share This Article

The Lean Six Sigma approach measures the number of defects in a process of an organization and helps to eliminate those defects by reducing variations in the process. The main goal of this approach is ‘continuous improvement’ in the process. To achieve this goal Six Sigma methodology follows a well-designed model known as the DMAIC methodology.

The DMAIC Methodology in Lean and Six Sigma is a well-defined quality management approach that aims at improving the effectiveness and efficiency of an existing process or product through continuous quality improvement and defect reduction. It is used when an existing product or process requires improvement to meet customer requirements.

Trying any new improvement can be intimidating, hence make it helpful for you, we have broken down all the details of DMAIC so that you can give it a try with confidence.

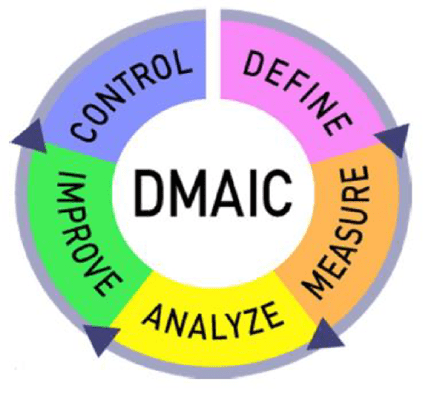

DMAIC Methodology and Phases

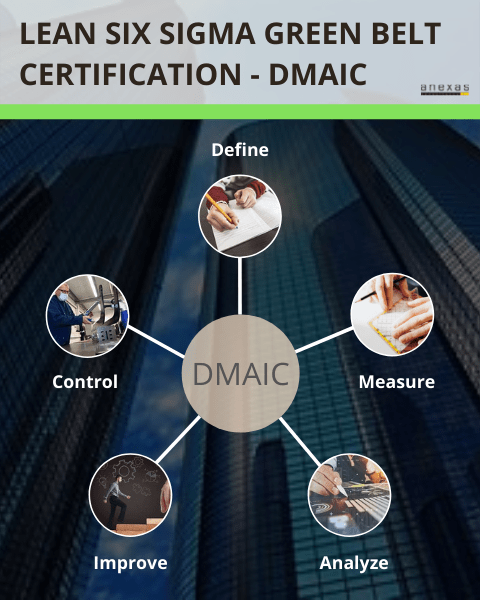

DMAIC stands for Define, Measure, Analyze, Improve, and Control. The five steps represent an improvement cycle that is meant to be repeated frequently identify best practices and move ever closer to perfect processes.

Define: This is the first phase where the purpose and deliverables of the project are identified. We make a high level process map known as SIPOC , collect Voice of customer(VOC) and finalize the project charter. This phase sets the direction of improvement.

Measure: In order to understand the size and scope of the problem, we need to measure the problem by collecting sufficient baseline data of the output. With the help of basic statistical tools, we understand the distribution of output. In the measure phase we identify the current performance of the process to identify the actual gap between desired performance and actual performance. Some of the tools like DPMO, sampling, Normal distribution, Process capability are used in measure phase.

Analyze: In the Analyze phase all possible causes or factors affecting the output are identified. They are then prioritized and validated. Here we map the process and identify the waste. A few other tools used here are a fishbone diagram (Watch now), Pareto chart, scatter plot, and box plot (Watch now). Hypothesis tests like ANOVA, Chi-square, Correlation, and regression are used for statistical validation.

In the improving phase we generate ideas to take care of the root causes using lots of tools like brainstorming, mistake proofing, and FMEA.

The team focuses on developing the solutions, testing the solutions by having pilot testing and implementing the solution. We check the process capability again to confirm the improvement and compare the before and after states using control charts.

Control: In the control phase we ensure that the improvements are sustained for a long time using process management and control charts. Documentation of new processes and training of the team members helps to sustain the improvement. Control charts help to understand the process variation on an ongoing basis. Other tools like SOPs, training plans, communication plans, implementation plans, and visual controls are used in the control phase.

What is Lean Six Sigma? Lean Six Sigma DMAIC approach can be used to improve the existing processes in the organization. Lean Six Sigma DMAIC approach can be used for incremental improvement as well.

Lean Six Sigma Green Belt Certification Overview of DMAIC Methodology example 1

Manufacturing Shop Floor Yield Improvement

In this DMAIC example, we have a repetitive manufacturing process rich in operational data, making it a good candidate for a Six Sigma analysis. We’re making products and want to increase yield.

- DEFINE: Identify specific products (e.g. three SKUs), product flow and the goal (increased yield, not faster throughput).

- MEASURE: Clearly defined metrics to be used. Monitor for an adequate time to gather statistically meaningful baseline data.

- ANALYZE: From the data, identify and address outliers, look for trends, and assess the mean and standard deviation. Use root cause analyses e.g. Five Whys, Cause and Effect Diagrams to identify variables that impact the yield.

- IMPROVE: Define and put in place countermeasures to address root causes that have been identified. Monitor the process to confirm that the desired yield improvement is achieved.

- CONTROL: Implement measures to maintain improved performance (e.g. standard operating procedures, process control).

Lean Six Sigma Green Belt Certification Overview of DMAIC Methodology example 2

Cleaning Your Garage

Before you take on an organizational effort with a larger team and longer timeframe, you can try the process at home. Imagine you want to clean up your garage so you can fit a new motorcycle inside. You could use Lean methods to accomplish this goal.

- DEFINE: Identify the scope of the cleaning project (cleaning the garage, not the whole house).

- MEASURE: Pace of the square footage of the overall garage and the open floor space. Set a goal for the required amount of open floor space. (You may eyeball this, but it is a measurable area.)

- ANALYZE: Understand the types and amounts of materials currently in place and the available storage locations.

- IMPROVE: Use Lean tools e.g. 5S (Insert link here) to execute cleaning and organizing, including removing unessential materials. Install improved vertical storage facilities to minimize floor space used.

- CONTROL: Label storage spots. Put “after” photos in place as ongoing targets. Conduct weekly audits to ensure “stuff” doesn’t accumulate.

However, the application of DMAIC is limited to improving existing processes only. It doesn’t address the design of new products, services, or processes. For developing a new product, service, or process, there’s a modified version called DFSS (Design for Six Sigma). The process most often used in DFSS is called DMADV. DMAIC and DMADV are methodologies of Lean Six Sigma that are used everywhere to improve processes.

Also read: Lean Six Sigma Green Belt Certification Overview of Poka-Yoke