Lean Six Sigma Green and Black Belt Certification

Master Efficiency and Drive Quality with Six Sigma methodologies

4.7

(35,000)

(35,000+ students enrolled)

Course Description For Lean Six Sigma Green Belt and Black Belt

Are you ready to take on leadership roles? Welcome to the Anexas Lean Six Sigma Green Belt and Black Belt certification course. Lean Six Sigma consists of a proven methodology that improves processes, reduces waste, increases customer satisfaction, and improves profitability. Lean Six Sigma Green Belts and Black Belts imbibe skills that can effectively shift the working structure of a company for the better with anybody from any background being able to take this course to cause such shifts to advance their careers.

Anexas Lean Six Sigma Green Belt Certification course trains in techniques to improve the quality and consistency of products and services. Anexas Lean Six Sigma Black Belt Certification course upskills leadership skills to prepare people for managerial or leadership roles, contributing directly to a business’s success. Anexas has trained more than 75,000 Green Belt and 25,000 Black Belts worldwide.

The Lean Six Sigma Green Belt and Black Belt course is a combination of Green Belt and Black Belt courses that enables professionals to take the courses together hassle free and get certified in less time. The certification course provides two independent certifications. Lean Six Sigma Green and Black Belt course is a 6-days course, 3 days for each course.

Certifications you will receive

- Lean Six Sigma White Belt

- Lean Six Sigma Yellow Belt

- Lean Six Sigma Green Belt

- Lean Six Sigma Black Belt

- GB + BB project certificate

- Lean Expert certificate

- PDU certificate

- Minitab certificate

- 7QC certificate

- FMEA certificate

- 5s certificate

What you'll gain

- Complete 2 Live real-time projects during the training. Data will be provided by Anexas

- 2 Free live project recordings

- 2 hours of Free live project guidance every week from industry experts

- Lifetime access to course materials and Free eBooks

- Lifetime access to online live classes at no extra cost

- Course Content is Aligned to ASQ®, CSSC and most of the recognized syllabi

- 50 worked out projects from various industries

- Free 60 PDUs certificate from PMI for attending the course

- Mock interview sessions once a week

- One-on-one live sessions for missed classes

- Simulation exams to prepare for ASQ®, CSSC and all recognized exams

- Lifetime membership to Anexas Alumni group with placement assistance

- More than 10 complementary online courses

- Online 24*7 Customer support

Course Content for Lean Six Sigma Green Belt

- Introduction to class

- Introduction to Anexas

- Course purpose & objectives

- What is Six Sigma

- History of Six Sigma

- Estimating process sigma

- Understanding Variation

- Overview of DMAIC

- Overview of DMADV

- Case study

- DMAIC storyboard template

- Project Selection Criteria

- Team charter

- Project Charter

- Elements of Project Charter

- Quality, systems, and processes

- Work as a process

- What is VOC and importance

- Defining the customers

- VOC data collection plan

- Reactive/proactive data collection systems

- Analyzing customer data – affinity diagram

- Kano model

- Defining CTQs

- Setting specifications for CTQs

- VOC data collection plan

- Understanding Processes

- SIPOC

- Examples on SIPOC

Define Phase

- Basic statistics and introduction to Minitab

- Normal distribution

- Mean and standard deviation

- P-values

- How data can help

- Data characteristics

- Five-step data collection process

- Step 1: Clarify Data Collection Goals

- Stratifying data

- Types of data

- Step 2: Develop Operational Definitions and Procedures

- Operational definitions

- Sampling approaches

- Determining sample size

- Population versus process samplingChecksheets

- Step 3: Validate the Measurement System

- Problems with measurement

- Desired measurement characteristics for continuous variables

- Gage R&R study

- Gage linearity study

- Checking a measurement system for discrete data

- Time-ordered data

- Understanding variation

- Variation versus specifications

- Taguchi Loss Function

- Types of variation, appropriate responses

- Special cause, common cause

- Plots of variation

- Control charts

- Specifications and control limits

- Develop a focused problem statement

- Identify potential causes

- Brainstorming, Five Whys

- Understand relationships between potential causes

- Might-cause check

- Cause-and-effect diagram

- Tree diagram

- Prioritizing Input Variables

- Verifying cause-and-effect data

- Histograms

- Scatter plots

- Pareto Charts

- Box Plots

- Process maps

- Identifying Value-Added path

- VA/NVA analysis

- Identifying flow issues

- 8 wastes

- Cycle time

- Bottlenecks

- Value Stream Mapping (VSM)

- Involving people

- Lean solutions

- Generating solution alternatives

- Evaluating solutions

- Prioritization matrix, Pugh matrix

- Task and timeline planning

- Budget and resource planning

- Planning for change

- Planning to check

- Potential problem analysis

- Piloting

- Implementing the plans

- Quantifying results

- Evaluation and reactions

- Link improvement to management system

- Methods for monitoring and control

- Ongoing data collection, process control

- Variation and individuals charts

- Control charts for high-volume processes with subgroups: x bar and r charts

- Control charts for discrete data: p, np, c, and u charts

- Project closure

- Closure checklist

Course Content for Lean Six Sigma Black Belt

- Introduction to class

- Introduction to Anexas

- Course purpose and objectives

- Recap of key DMAIC concepts

- DMAIC roadmap

Lean Six Sigma projects case studies

- Quality function deployment

- Projects selection criteria

- Measurement system analysis

- Variable gage R&R

- Measurement system analysis

- Attribute gage R&R

- Introduction to hypothesis testing

- Hypothesis testing steps

- Bull and alternative hypothesis

- P-values

- Central limit theorem

- Hypothesis tests Test of means

- 1-z, 1-t test, 2-t

- Paired tests

- Test of means for 2 or more than 2 samples – ANOVA

- 1. 1 sample sign

- 1 sample wilcoxon

- Mann-Whitney

- Kruskal Wallis/ Moods Median

- 1-Proportion, 2-Proportion

- Comparing two or more group proportions: the chi-square test

- Sample sizes for hypothesis tests

- Review of hypothesis testing

- Correlation

- Regression

- Introduction to linear regression

- Basics of regression analysis

- General procedures for doing regression analysis

- Multiple linear regression

- Working with multiple regression

- General procedure for multiple regression

- Curvilinear regression

- Regression with discrete x’s

- Logistic regression

- Review of regression

- Showcase projects

- Projects review completed by participants

- The factorial approach to designed experiments

- Designing a full factorial experiment: MSD 23 example

- Planning and preparing for a designed experiment

- I-MR, X Bar R

- p, np, c, u Charts

Project review

Key Benefits of Lean Six Sigma Green Belt and Black Belt

Enhance your career with Lean Six Sigma courses

Hone your problem solving, leadership, and process improvement skills and advance your skill set

Join the industry of your choice

The Lean Six Sigma tools and techniques are applicable in all industries in equal measures. You can join the industry of your choice.

Internationally available opportunities

Get international opportunities. Lean Six Sigma is one powerful certification course that is valued everywhere

Become an internal consultant or an adviser to your company

Get better job roles and salaries after becoming a certified Lean Six Sigma course.

Deepen your business understanding

Lean Six Sigma certification course encourages you to think outside the box. It gives you a clear insight of the business and has a systems approach.

Get Project Management experience

The more you climb up the Lean Six Sigma ladder, the more project management experience you gain

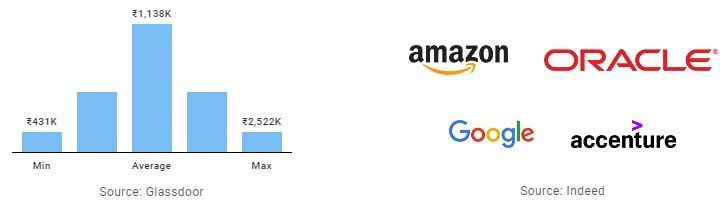

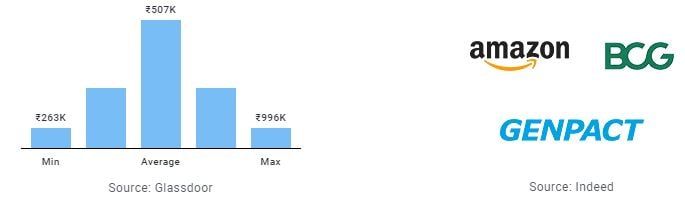

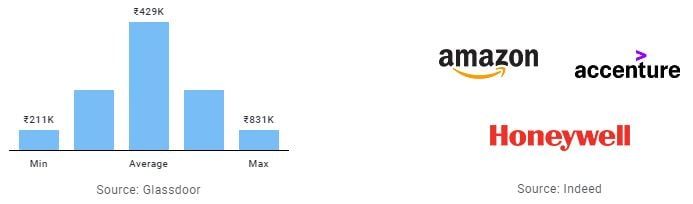

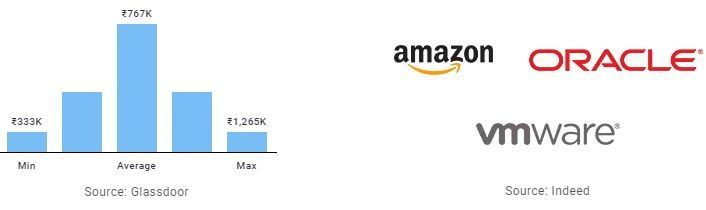

Lean Six Sigma Green Belt and Black Belt Salary Benefits

Learning from the Best trainer

Amitabh Saxena

Lean Six Sigma Master Black Belt | CEO, Anexas Europe

Amitabh Saxena, CEO of Anexas Europe has done some great work in the quality domain. He has an experience of more than 33 years. He is also the founder of Anexas and will be your trainer for the course. He has consulted Fortune 100 organizations including ADNOC, Dell, SABIC, Aramco, Ministry of Health, DP World, Alfuttaim Motors, EMC2, Bank Muscat, TATA Business services, Deloitte , TATA motors finance ltd, Steel authority of India, Indian railway , Colgate Palmolive , Novartis, Novozymes Denmark, HP, Tech Mahindra, Reliance, Bharat Petroleum, Maersk ,Cisco and the list goes on.

This course includes

- 30 hours of Live interaction

- Study materials

- Certificate of completion

- Digital badge

- 10+ complementary courses

- Community Access

Accredited By

View Certificate

Training options for Lean Six Sigma Green Belt and Black Belt

Self Paced Learning

Features

- Training conducted by renowned Master Black Belt Amitabh Saxena

- Project guidance by Amitabh Saxena

- Lifetime access to course materials and videos

- One free one-on-one session with renowned Master Black Belt Amitabh Saxena

Features

- 30 hours of online live training

- Additional 50 hours of recorded training content

- Live interaction with instant query clarification

- Free project completion during the training

- Lifetime access to course materials and videos

- One free one-on-one session with renowned Master Black Belt Amitabh Saxena

- Revise the online live course again at no additional cost

Classroom Training

Features

- 30 hours of classroom sessions.

- Additional 50 hours of recorded training content

- Training conducted in cities worldwide

- Hardcopy of the training material

- Free Online guidance and mentoring for your projects

- Free project completion during the training

- Lifetime access to course materials and videos

Corporate Training

Features

- Customised course content and duration for your organisation

- Company-specific training with company-related examples and case studies

- Live interaction with instant query clarification with renowned Master Black Belt Amitabh Saxena

- Project completion during the training

- Lean Six Sigma tools and techniques aligned to the organization

Industry Projects For Lean Six Sigma Green Belt and Black Belt

FAQs

Everything you need to know about Lean Six Sigma Green Belt and Black Belt.

Still have questions?

Can’t find the answer you’re looking for? Please talk to our friendly team.

A Lean Six Sigma Green and Black Belt course is designed for professionals who aim to work in leadership roles and work directly for the success of businesses. We train in techniques and concepts that can be applied to improve any process in any industry. We train in tools and prepare individuals for managerial roles with leadership skills.

Yes. Once you pay the fees for the training, all the other costs such as examination costs, study material costs, tools and software costs, and project training costs will be included and no extra charges will be levied.

We have flexible payment options.

- You can make full payment.

- You can choose an installment. Pay a token amount during registration, and pay the remaining balance anytime before the course concludes.

Choose from multiple payment options at Anexas:

- Card payment

- Net Banking

- Cash

- UPI payments

- Tabby

We have an easy cancellation policy made easy!

- If you cancel your registration 72 hours before the training starts, a 10% administration fee will be deducted.

- Unfortunately, no refunds will be issued for cancellations made after that.

- However, if you’ve already made the payment, you can reschedule your training to another batch at no extra cost. We value your convenience and strive to accommodate your needs.

Other Related Courses

Lean Six Sigma Green Belt

Experience the true power of Lean Six Sigma Green Belt with Anexas!

4.7

(35,000)

(35,000+ students enrolled)

Lean Six Sigma Black Belt

Experience the true power of Lean Six Sigma Black Belt with Anexas!

4.7

(25,000)

(25,000+ students enrolled)

Lean Six Sigma Master Black Belt

Experience the true power of Lean Six Sigma Master Black Belt with Anexas!

4.7

(30,000)

(25,000+ students enrolled)

PMP Certification Course

Experience the true power of PMP Course with Anexas!

4.7

(25,000)

(25,000+ students enrolled)

CPHQ Certification Course

Experience the true power of CPHQ Course with Anexas!

4.7

(25,000)

(25,000+ students enrolled)

Power BI Certification Course

Experience the true power of Power BI Course with Anexas!

4.7

(15,000)

(15,000+ students enrolled)